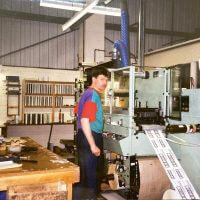

1980

Hine Labels began life in a back room at the Old Rectory in Whiston, Rotherham, where the Hine family lived. Peter Hine retired from his engineering career, and bought a Hot Foil printing machine from his employer. The idea was that he’d supply his old employer with labels. Quickly, Peter gained a reputation locally as a talented label-maker.